LS252D Leeb Hardness Tester

- Delivery Charge: Depend On Products Quantity and Weight*

- Inside Dhaka: 60 Taka

- Outside Dhaka :150 Taka

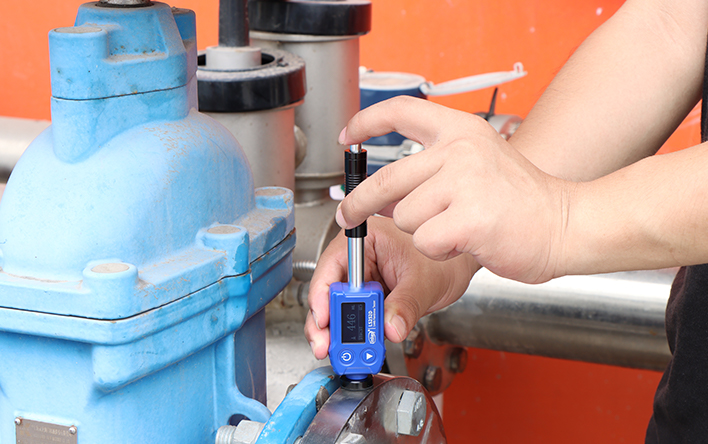

LS252D is an advanced state-of-the-art palm sized metal hardness tester which incorporates the impact device and controller into one unit. It easily fits in a pocket. It used lastest dual-coil technology which makes the tester to have extraordinary accuracy: ±6 HL and good repeatability:6HL. It adopts orientation sensors that will compensate the measurement errors in different impact directions automatically to ensure the accurate data, with durable metal housing and OLED display screen. Equipped with impact device D, LS252D is especially suitable for almost any object, polished parts and heat-treated surfaces or the situation requiring a large number of tests. The battery can be charged simply from USB port, also it has a customer re-calibration function.

Application

LS252D handy Leeb hardness tester is suitable for testing the hardness of materials such as steel, cast steel, alloy steel, stainless steel, gray cast iron, ductile iron, cast aluminum alloy, copper-zinc alloy, copper-tin alloy, pure copper and forged steel. The instrument can be widely used in machine tool guides, automotive chassis, heavy workpieces, mold cavities, bearings, pressure vessels and installed machinery or assembly parts and can help manufacturers to carry out product quality inspection and reasonable process analysis.

Parameters

| Parameters | Value |

|---|---|

| Probe | Impact device D |

| Hardness Scales | HL, HV, HB, HS, HRA, HRB, HRC |

| Measurement Range | HLD: (170-960); HV(83-976); HB(30-651); HRC(17.6-68.5); HS(26.4-99.5); HRB(13.5-100); HRA(60-85.8) |

| Resolution | 1HL |

| Accuracy | ±12 HL, ±6 HL typical |

| Repeatability | 6HL (factory standard) |

| Display | 128 * 64 dot matrix OLED |

| Power Supply | Rechargeable lithium battery 3.7V@250mAh, full charge for over 5000 continuous measurements |

| Size | 148*34*24 mm |

| Weight | About 68 g |

| Working Temperature Range | -10~50℃,0~85%RH(no condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(no condensation) |

Features

Integrated design, easy operation

Pen-type Leeb hardness tester is lightweight and portable with easy operation

High accuracy with patented dual-coil technology

Cutting-edge dual-coil technology bring the tester extraordinary measurement accuracy and good repeatability

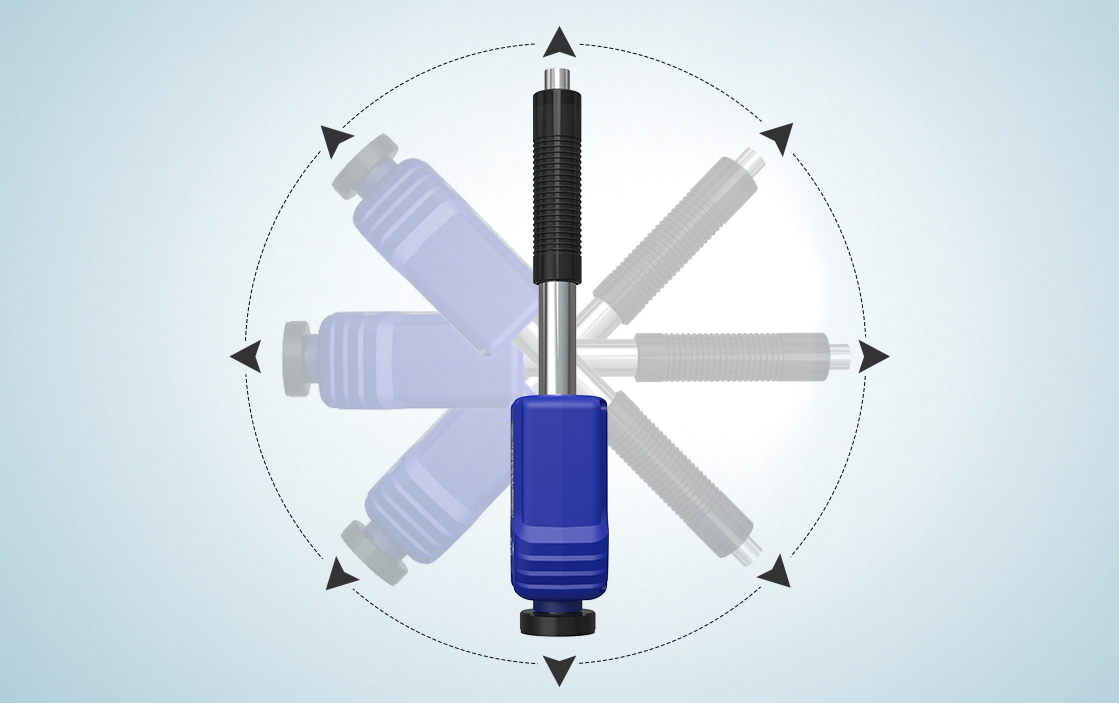

Direction sensor inside the probe will compensate the measurement errors in different impact directions automatically

The instrument can measure at any angles. Featuring a built-in direction sensor, the probe can automatically compensate the measurement errors in different impact directions. Multi-angle measurement is easy

Capable of measuring a wide range of metal materials

With 10 built-in metal materials, including steel, alloy tool steel, stainless steel and grey cast iron, the instrument can be used in a wide range of applications and industries to meet the demands of everyday work

Conversions to different hardness scales

LS252D hardness tester provides a variety of hardness scales, which can be converted between Leeb (HL), Vickers (HV), Brinell (HB), Shore (HS) and Rockwell (HRA/HRB/HRC) eliminating the cumbersome steps of manual table lookup

Impact device is made of Tungsten carbide

LS252D impact device is partly made of Tungsten carbide, and its hardness is almost equal to the diamond

USB port is used to charge to battery

Using rechargeable lithium battery, the battery can be charged simply from USB port

Customer re-calibration allowed

Users can calibrate the standard parts to reduce the error

Reviews

There are no reviews yet.